A week out the shop

Published 26 Oct 2020

I didn’t get much time in the workshop this week, mostly down to non-guitar related contracting absorbing most of time with a crisis at one of my clients just as we were about to ship something; I managed to fix all the things, but it meant no real workshop time. But that’s how the cookie crumbles some weeks when you spread your time between things that pay the bills and things you love. But I hate not doing regular week notes, as I feel it’s important to mark that not all weeks go to plan, so here’s the little I did manage to get done.

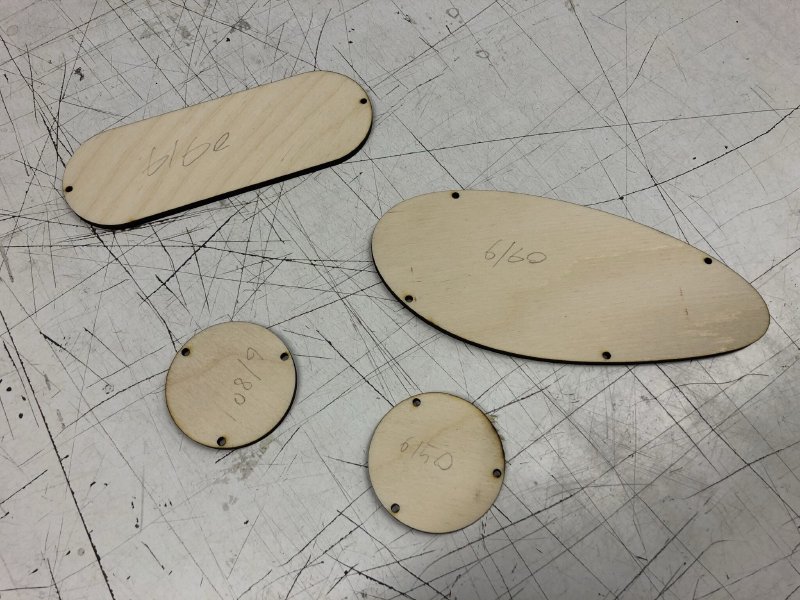

Last week I routed out the lips on the control cavities for the two guitars I’m working on right now, and so I went to make some covers for them. Before I use good wood, I made some test plates in scrap on the laser cutter:

The nice thing about any workshop is you build up a lot of scrap material to use for things like this (indeed, the problem is usually having the discipline to throw some of it away!); clearly someone had been making groovy shapes before me - all very yellow submarine to my eyes :)

After ten minutes or so I had all the covers cut:

The numbers on them are the speed and power settings I had the laser at, as I tried to work out what was the least power I could get away with to cut through. I had expected this to require a few iterations to allow for the laser cutter making things slightly smaller than you want (as it burns away material) and so I’d make my designs slightly bigger to compensate.

The reason I wanted to use the least power I could get away with was to minimise the material loss. In my mind this makes sense, though I must confess now that I write this I’ve never actually measured it - so there’s a fun experiment next time I’m at the laser. I do know that if you generally want to go as fast as you can to minimise laser dwelling, unless you have sharp corners, in which case you’ll find the laser wobbles as it changes direction at speed and you’ll see little oscillations for the first 10 mm or so as it sets off in the new direction.

Anyway, these test pieces all fitted well enough, as you can see here on the Corvette body:

and here in the other as-yet-unnamed build:

I still need to test that the holes are not close enough to the edges that when I counter-sink the holes they don’t clip the outer edge, but I forgot to take the screws I’d ordered for these into the workshop with me (as I say, it’s been a stressful week).

Obviously the ply looks a bit uninteresting next to the grain of the ash and poplar in the two bodies. My plan is to use some maple that I have left over from making necks that should have a more interesting texture to them, and I’ll stain it a contrasting colour to whatever these end up looking like to make the covers more of a feature.

The other bit of work I did was CAD work, which I can’t really share at this point as there’s nothing much to show. Someone asked me if I could make them a body for a bass with some particularly ornate design feature, and I’ve been trying to work out how I’d build it. The design is almost a traditional solid body design, except for one flourish which I imagine needs to be hand carved. But the challenge is how do you best get there?

For me the only way to figure that out is by trying to make the design in CAD, getting the features I want in the design whilst understanding how I’d make them at each stage. It’s very easy in CAD to design something you can’t build, so even though I make the guitars by hand for the most part, as I’m making the CAD model, for each feature I add I try to ask how I’m going to make it, not just to draw blindly.

For example, what if you need a sharp concaved corner in your design? Well you can’t make that with a router as that will only go down to a curved corner that’ll match the radius of the bit you’re using, and that minimum radius will be proportional to things like depth of cut and material density, so you’ll probably need to use a band-saw or scroll-saw for that corner. That then means can you get a band-saw to that part, but not if it’s a pocket, but you might get a scroll-saw there. And so on. For complex builds like an instrument you need to plan ahead as you really don’t want to discover that you’ve committed to a design you can’t make after spending time and money to get half-way through.

So far for the bass body that someone inquired about one it’ll need a bunch of different approaches: it’ll need to be CNC routed in part, tweaked with a scroll-saw, and then carved by hand just to get this one feature.

Hopefully I’ll post more details on this later as it moves along.

On the topic of CAD I note that my “startup” subscription to Autodesk’s Fusion 360 is about to expire. In the past this has been something I’ve been able to renew, but the wording on the website implies that this special status might no longer be renewable, so I’ll have to ping their support.

Fusion 360 has been the source of much debate in the maker community in the last month or so as they added significant restrictions to the free personal/hobby license at short notice. It’s always a hard thing to do when trying to balance offering a free version to help grow a community around your product and ensuring that you can actually make money, but Autodesk kinda fumbled the ball a little here by adding these restrictions at such short notice, and initially cutting off one common Maker use-case that they then later back tracked on.

So I’d not be surprised if the startup license that I use has similarly been restricted - I’ll keep you posted on how that turns out.

I mentioned a few weeks ago that the amp I built myself had burnt itself out, and I’d switched to using my workbench amp for practice. Well, that got a bit tedious and I’ve temporarily switched up to the larger Blackstar HT20 amp that I bought for doing shows (remember those?) and demos.

I bought the HT20 as a middle of the road amplifier - you can make it more Fenderish or more Marshall like, and although it doesn’t really nail either, its enough that in shows/demos potential customers can dial in a tone that’s close to what they’d have on their own rig. But I’d never have described it as an inspiring amp.

Well, I have to say I was wrong on that having played it for a week, I find myself playing more guitar than I have done for a while. Whilst I love the little 5W amp I made myself, being based on a 1950s Fender Champ it is a bit of a one trick pony, and after 3 years without realising it I’d become a little bored of that same sound every day. Whilst the HT20 doesn’t have the same character, it has a lot more fidelity to its sound, and so I’ve been drawn in exploring different tones from my guitars and pedals, hearing them with fresh ears.

So, if you find yourself bored with your playing, particularly whilst it’s been harder to play with other people this year, then perhaps a changing things up to give you more variety and options might help - it’s certainly got me playing a lot more again.

And that’s it. Hopefully I’ll get more time in the workshop once bits start arriving in the post (including my much delayed band-saw :).